Ventilation radiator

The Ventilation radiator is an outdoor air intake device for mechanical exhaust ventilation systems. It allows the supply of air to be filtered and heated and brought to the room without any draft or noise. At the same time, the ventilation radiator acts as a normal heating radiator. In fact, the ventilation radiator is a modern panel radiator equipped with an air unit. (Fig. 1).

Figure 1. Ventilation radiator

Ventilation radiator function

Ventilation radiators are mostly used in the Nordic countries, and especially in Sweden where there is an installed base of one million units. Low pressure ventilation radiators are also used in hybrid ventilation systems, where the required negative pressure needed for outdoor air intake is achieved by exhaust air fans when the natural temperature-pressure differences are not available.

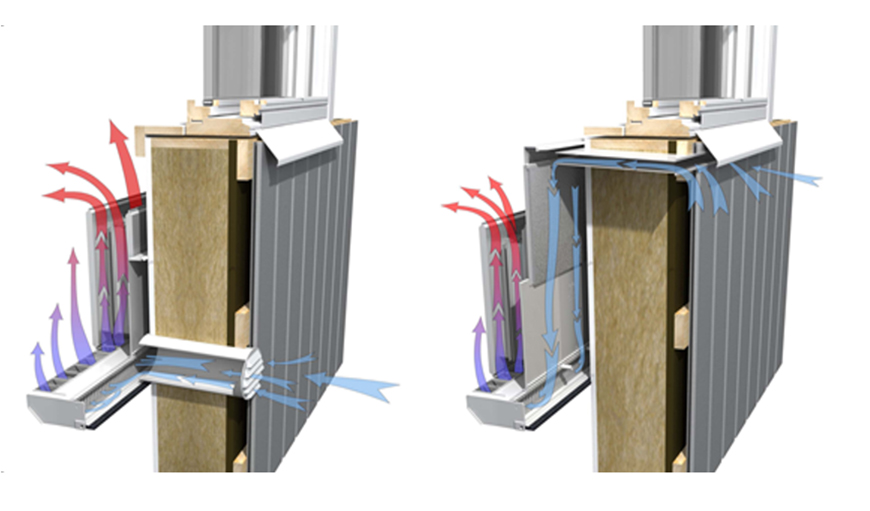

Figure 2. Straight wall duct and telescopic duct

Figure 2 shows the cross-sectional projections at the wall duct level of two frequently used wall ducting options, a straight wall channel and a telescopic channel under the window frame.

In addition to outdoor air filtration and heating, an important feature of the ventilation radiator is its low air pressure drop. The filter options of PurmoAir are F9, F7 and coarse filter.

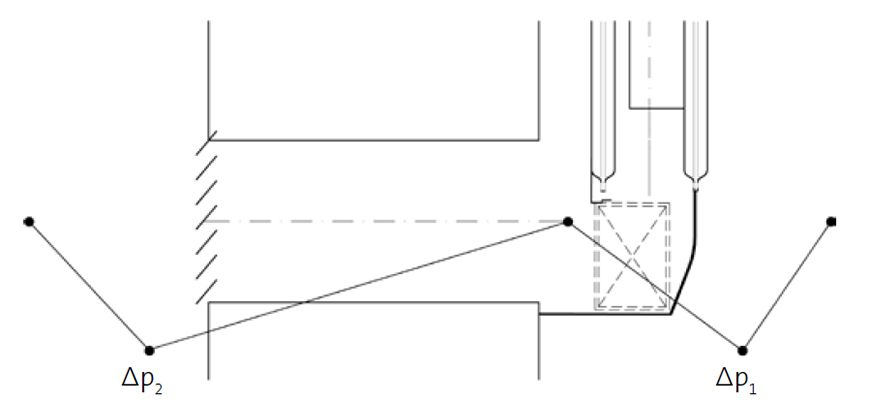

Figure 3. Pressure drop schematic of ventilation radiator

The total pressure drop across the building envelope to the room depends on three main resistance factors: the external grille plus the wall ducting Δp2 and the air unit, filter plus radiator, Δp1 (Fig. 3).

For example, the total pressure drop of PurmoAir with an outdoor air flow of 10 L/s with a Ø 100mm wall duct, open rate of 75% at the inlet grille and a filter type F9 is 11 Pa. If using a Ø 125mm wall duct the total pressure drop is 8 Pa. These values are obtained from PurmoAir's sizing system. The air flow can be adjusted and, if necessary, also shut off.

Flow resistance of incoming air is low and much lower than in normal air vents. This is necessary for hygienic reasons in order to avoid air infiltration and influx of microbes and impurities, e.g. from the old building structures.

When PurmoAir's own 38 dBA noise reduction is not sufficient for example, in areas with heavy traffic, silencer tube inserts of Øin100mm/Øout160mm are available, providing noise insulation levels of over 50 dBA. Even larger sound insulation can be achieved with Z-type silencers built into the outer wall.

Proper ventilation

How to achieve adequate ventilation, economically, energy efficiently and without drafts, is a key issue for the housing health, and the well-being and productivity of the occupants. Residential buildings have been given instructions and regulations, for example, with minimum flow rates of 4 L/s up to 7 L/s per occupant and a reasonable total outdoor air flow of 0.35 L/s to 0.5 L/s per dwelling floor m2. Typically, the whole apartment needs to have at least 0.5 air change per hour, i.e. the air in the dwelling changes at a rate of once every two hours: 0.5 1/h.

These guidelines are based on removal of body odors, material emissions, humidity and adverse health effects and occupant symptoms reported in the scientific literature. Carbon dioxide and moisture yields, and emissions of living and building materials must be removed from the dwelling through ventilation. It is especially important that the bedrooms have enough ventilation and that the exhaust air flow is continuous and controlled from the bathrooms, toilets and through the kitchen hood, in accordance with the need. The so-called controlled ventilation is emphasised in energy efficient and airtight buildings, both new and extensively renovated older buildings.

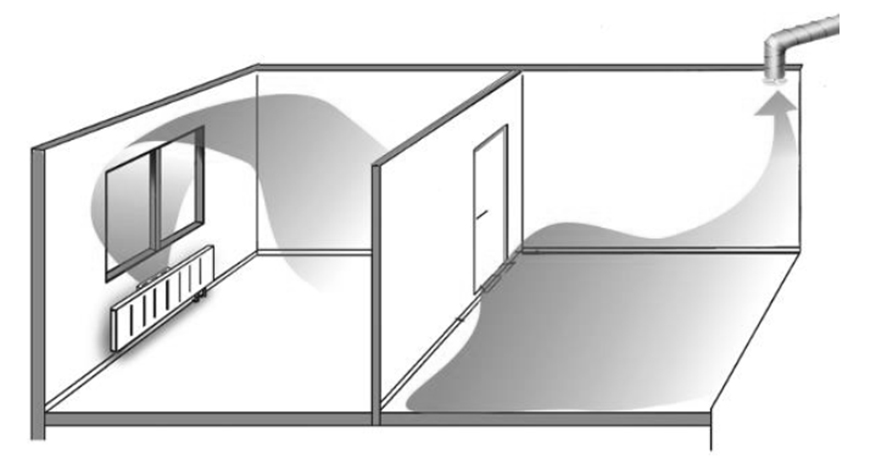

Figure 4. Controlled ventilation with central exhaust

Principle of controlled ventilation: The air flows from the "cleaner" rooms to the "less clean" ones, such as bathrooms and toilets, which have extraction (Fig. 4).

Self-heating effect and draft-free operation

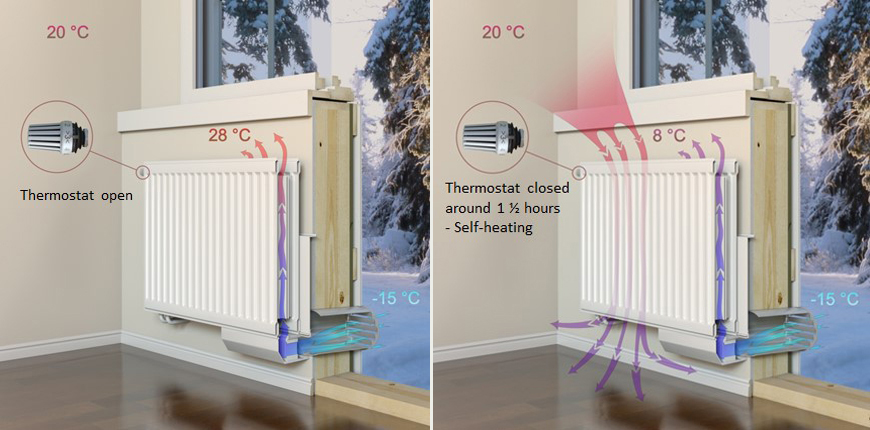

The Ventilation radiator has a self-heating feature. When the room temperature rises above the setpoint, for example 20°C, the thermostat valve automatically closes the radiator water circuit. The incoming outdoor air cools the radiator and after a while the radiator temperature can drop to below room temperature. Then the radiator starts to absorb the heat of the room through radiation and convection: The radiator water heats up and in turn heats the supply air. Figure 5 shows a PurmoAir self-heating case: The outdoor air flow of 10 L/s at minus 15°C warms up and stabilizes after one and a half hours to plus 8°C due to the self-heating phenomenon. Panel radiator type was 22-500-1400.

The thermostat re-opens the radiator's water circulation when the room temperature drops below 20°C.

Often the thermostat opens the water circulation much earlier than previously described, and thereby the supply air is significantly warmer - PurmoAir works virtually draft-free, and the supply air is heated even when the thermostat is in shutdown mode.

Figure 5. When the radiator temperature drops below room temperature the radiator starts to absorb heat from the room and the supply air warms up.

Other features of the ventilation radiator

- The heat output capacity of the radiator is high compared to a traditional radiator, often 30-40% higher. Due to its high thermal output, it is ideally suited for very low temperature heating systems.

- Typical design temperatures: flow 50°C and return water 40°C At the normal heating conditions the water temperatures are significantly lower, which provide perfect working conditions for heat pumps, for example. Even lower design temperatures can be used, for example, in warmer climates.

- Reacts faster than a conventional radiator, resulting in more accurate room temperature control.

- The return water temperature is often extremely low, even lower than room temperature, thanks to the thermostat function. This is useful for heat production efficiency.

- Is hygienic and easy to clean, no long ductwork systems.

- Can cool a room space, for example in spring, when free heat gains are high, typically from solar, people and electrical appliances, and when outdoor temperatures are still low.

- Serves as a great source of free cooling during summer nights due to its low pressure drop to cool the dwelling with cool outdoor air.

What types of buildings are suitable for the ventilation radiator system?

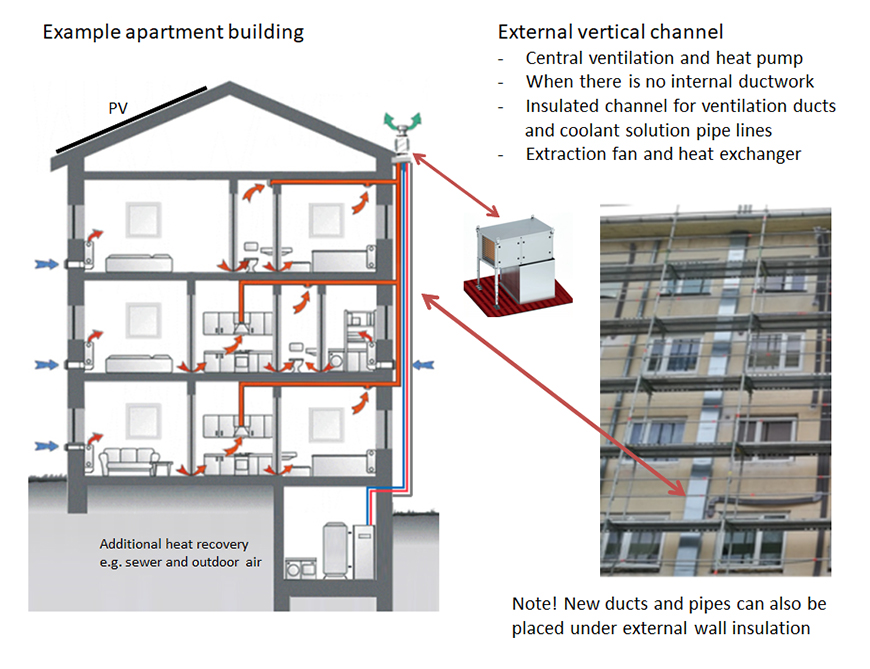

In principle, ventilation radiators are suitable for both new and old buildings that have a mechanical ventilation system, provided that the building is airtight. Exhaust air heat recovery is a must in modern buildings. With the help of an exhaust heat pump, the energy of the ventilation exhaust air is transferred to the domestic hot water all year round, and depending on the design, it can often almost entirely cover the heating requirements of the premises. When required, additional heat can be provided from sources such as electricity from a grid, a building’s own solar energy systems or micro-CHP, a combustion boiler or district heating. The annual COPa of the heat pump is high because the heat source has a constant room temperature throughout the year.

Ventilation radiators are among the best for deep-energy renovation. Renovation can be carried out even when residents are present in the dwelling, without the need for larger construction of ductwork, and with only the exhaust ducting needing to be renovated.

Ventilation radiators are especially suitable for apartment buildings (Fig. 6). Together with the exhaust air heat pump, a very cost-effective and energy-efficient refurbishment concept can be achieved.

Figure 6. Ventilation radiators and exhaust heat pump – a deep-energy-renovation concept for apartment buildings.