More energy, less resources, less waste

At Purmo Group’s UK manufacturing site in Gateshead, sustainability was the key consideration when selecting a new powder-coating booth system. They wanted a solution which was more energy efficient, would use less resources, and reduce the amount of waste going to landfill.

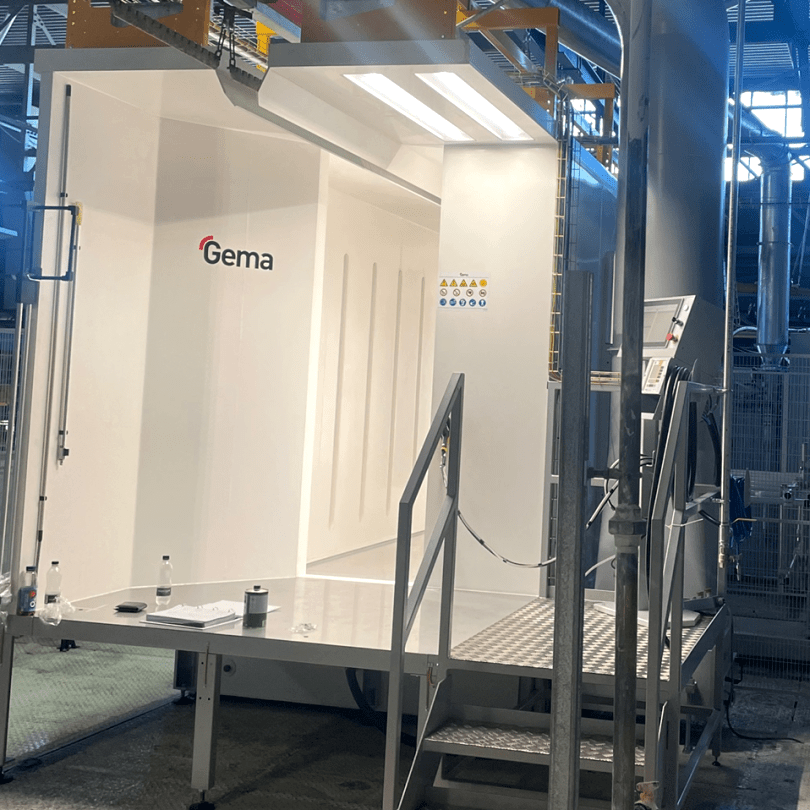

A full market evaluation led them to a powder coating system called MagicCompact, which utilises a combination of software and hardware to produce high-quality finished components with a much-reduced environmental impact.

The system was the first of its kind in the UK, and it represents a move towards intelligent digitalisation and Artificial Intelligence. Cloud-based, it draws intelligence from multiple areas of the plant, and provides digitalisation of all the coating parameters for the radiators being painted. It then uses this data to make autonomous decisions to optimise the painting process and reduce the consumption of resources.

Better use of resources, less waste

At the heart of the new system was EcoDrive, an energy optimisation tool, which automatically adjusts power usage whilst maintaining a high quality paint finish.. This has delivered a reduction in demand for electricity of up to 15% during normal operations. There has been a similar reduction in powder consumption due to high efficiency powder coating pumps, and an intelligent pressure monitoring system which has reduced the requirement for compressed air by 15% - 30%, depending on operating conditions.

As a further benefit, the amount of waste being produced has been reduced. The introduction of sinter-plate filtration has meant that much more powder is recovered. With a typical life-cycle of 10-15 years, compared with using traditional cartridge filters, this has resulted in a significant decrease in the amount of waste going to landfill.

Grant Lennon, Plant Manager said: ‘The new powder coating system has delivered all kinds of benefits. As well as reducing the resources needed and reducing waste, it provides us with data on the condition of the hardware, allowing preventative maintenance to take place to ensure it is kept in top condition, with no breaks in production. It is a real step forward in terms of sustainability, and we are delighted to have it in our plant.’